Technology

Inspections/Measurements

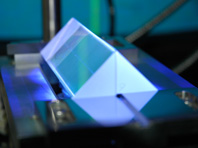

High accuracy meeting with strict standards

NITTO OPTICAL sets up its own standards to provide products that meet customer requirements. NITTO OPTICAL has established a quality management system for satisfying customers.

For instance, when measuring surface roughness RMS = 1Å (angstrom) or less and reflectance with R (reflectance ratio) ≥99.98% thin film coating, (deposition/sputtering), to guarantee these kind of quality, inspection/measuring equipments required to be in optimal environments.

NITTO OPTICAL has various inspection equipment, measuring instruments and testing devices are deployed to evaluate quality in each step, and defective products are prevented from flowing to the next process in advance.

Additionally, each device is controlled in order to maintain the measurement ability for satisfying numerical criteria.

For visual inspections, scratches and chips on each product are inspected by skilled inspectors.

To maintain stable product performance after delivery, a heat cycle inspection and humidity test etc., are conducted to confirm reliability in various environments.