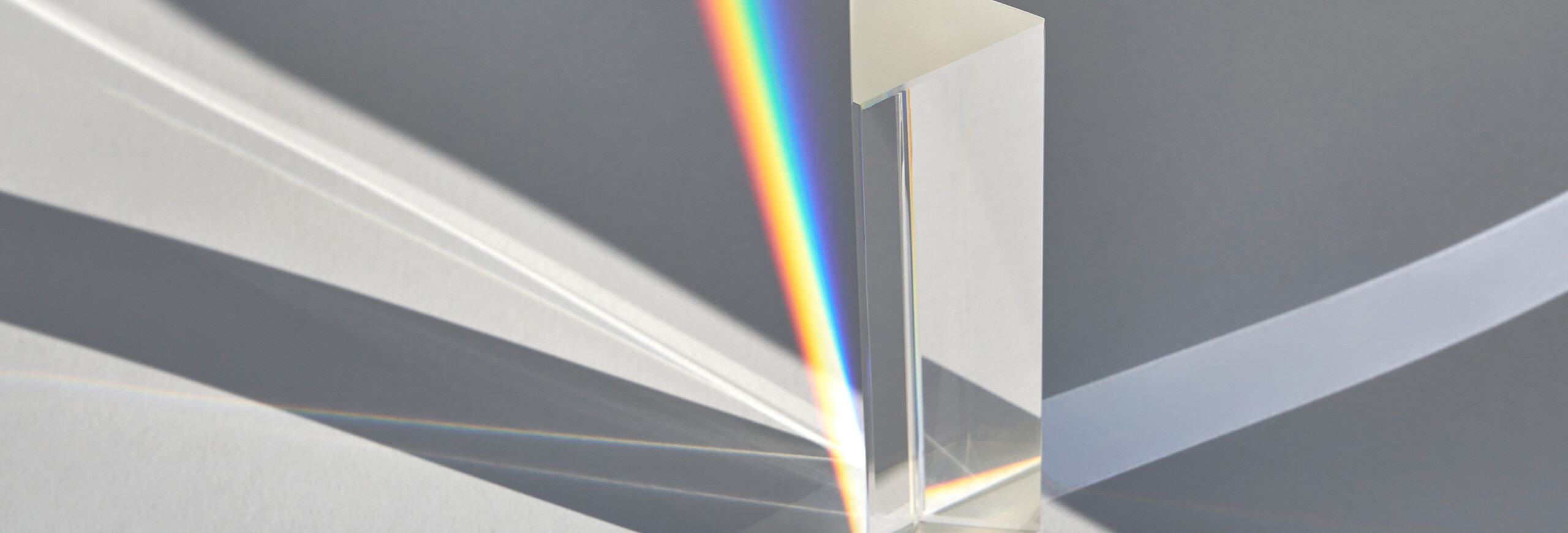

Technology

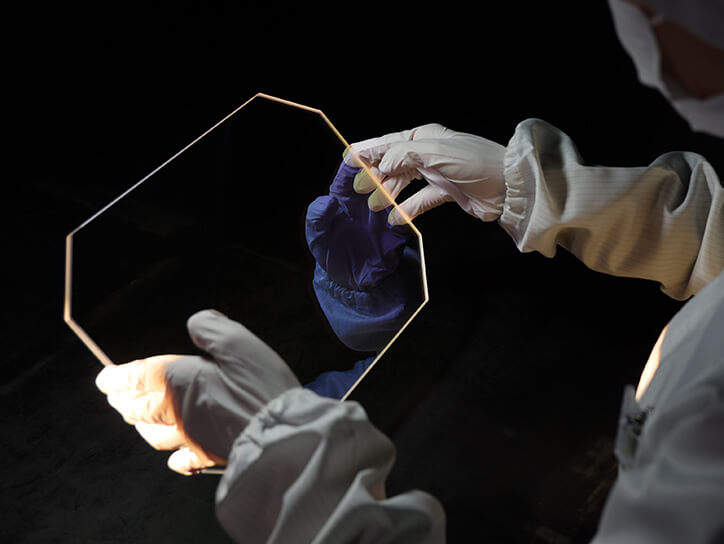

Integrated production system from prototype design to quality assurance of the finished products.

NITTO OPTICAL satisfies customer requirements with the world leading precision processing technology.

From prototype design and the selection of materials, in all processes of material procurement and inspection, grinding, polishing, coating (vacuum deposition/sputtering), bonding, cutting, cleaning, micro-patterning and optical system assembly, an integrated production system to achieve short lead time is established, and quality assurance is conducted on all production processes.

NITTO OPTICAL also accepts requirements for prototype processing and small-lot production as well as polishing, thin film coating and optical assembly only.

-

Prototype Design / Material Selection

Handling everything from prototype design and the selection of materials

-

Material Procurement

Implementing optimal material procurement and strict incoming inspections

-

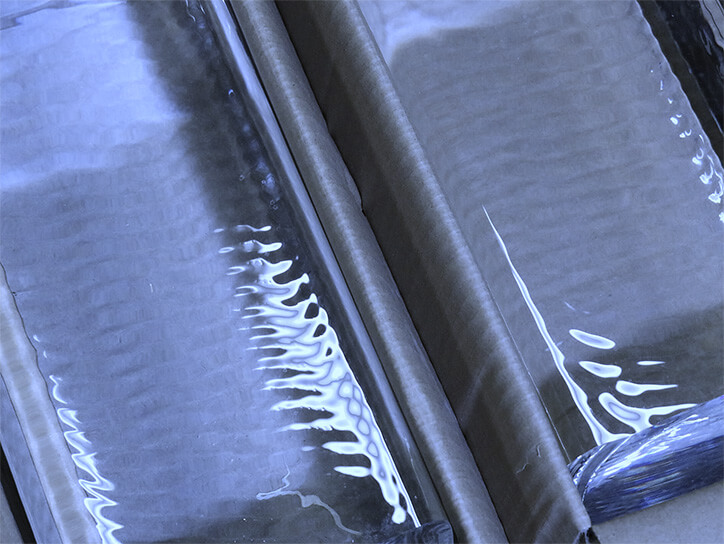

Grinding

Bridge to super high precision polishing

-

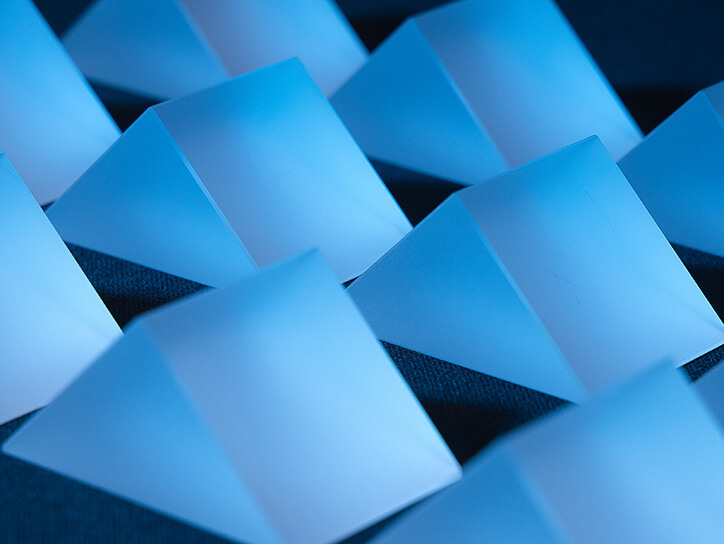

Polishing

Precision polishing for various optical materials

-

Thin Film Coating (Vacuum Deposition / Sputtering)

Additional performance to optical parts

-

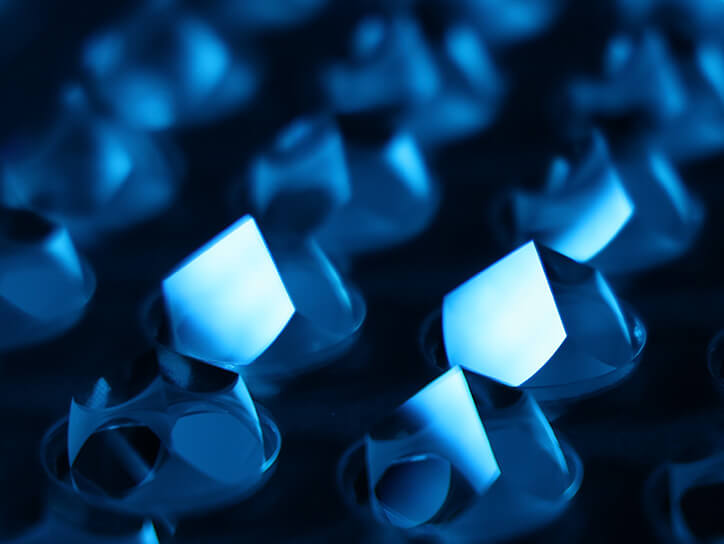

Micro-Patterning / Bonding / Cutting / Cleaning

Technology supporting microfabrication and integrated mass production system

-

Opto-Mechanical Assembly

Realizing optical performance through precise assembly technology

-

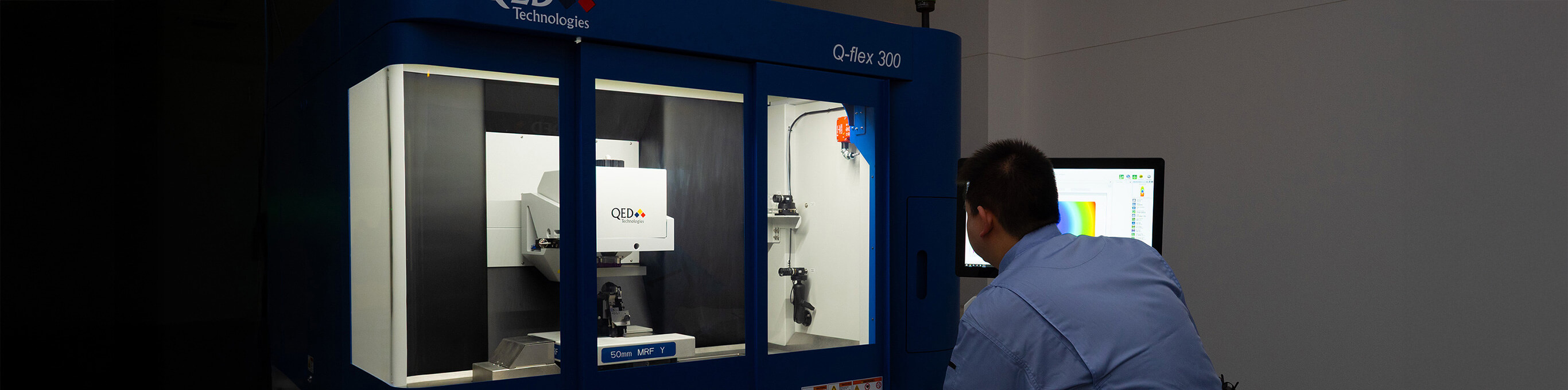

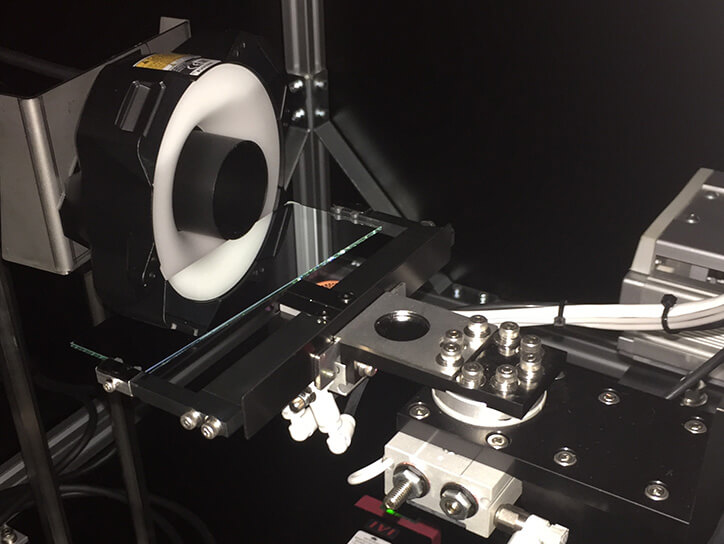

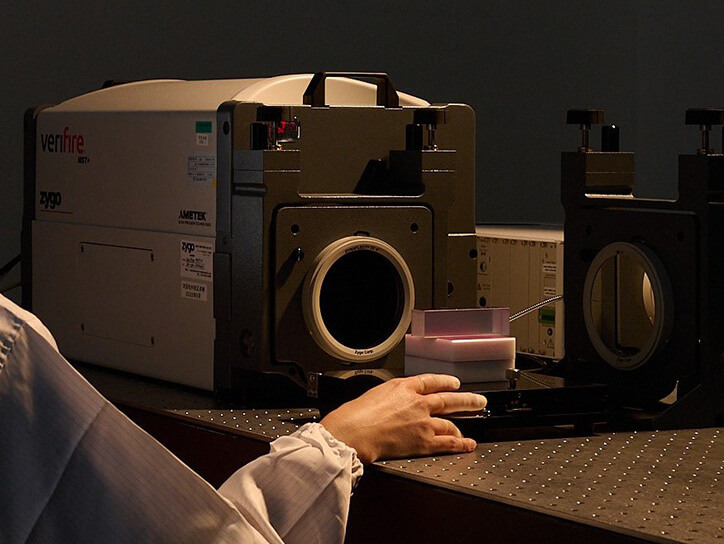

Inspections / Measurements

High accuracy meeting with strict standards

-

Quality Assurance

Total Quality Assurance and Environmental Management System